THE PREMIER ALUMINUM DIE CASTING COMPANY

We believe in satisfying customer needs with teamwork, passion, and dedication in a workplace that cares about people.

THE PREMIER ALUMINUM DIE CASTING COMPANY

We believe in satisfying customer needs with teamwork, passion, and dedication in a workplace that cares about people.

WE ARE PRECISION

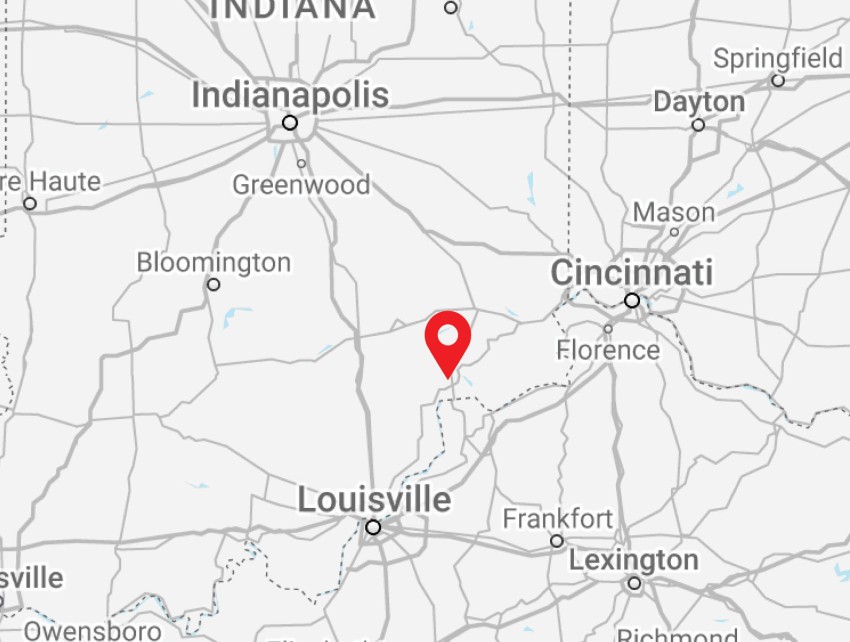

Madison Precision Products, Inc. maintains a position of leadership through innovative aluminum die casting technology and quality. From our facility in Madison, Indiana, we produce parts for our manufacturing clients worldwide.

WE ARE PRECISION

Madison Precision Products, Inc. maintains a position of leadership through innovative aluminum die casting technology and quality. From our facility in Madison, Indiana, we produce parts for our manufacturing clients worldwide.

OUR

CAPABILITIES

Our facility casts and machines high-quality aluminum parts for the automotive industry, in addition to exploring new technology for the use of aluminum diecast products. Our capabilities include:

- Die Casting

- Machining

- Sub-Assembly

- Inspection

OUR

CAPABILITIES

Our facility casts and machines high-quality aluminum parts for the automotive industry, in addition to exploring new technology for the use of aluminum diecast products. Our capabilities include:

- Die Casting

- Machining

- Sub-Assembly

- Inspection

WHO WE WORK WITH

Join our team at Madison Precision Products. We offer full time employees a comprehensive benefits package. View our open positions and apply today.

JOIN OUR

TEAM

CONTACT US